CAE analysis capability

In the process of process analysis in the early stage of mold design, our company makes full use of the design software CAE to conduct process simulation analysis. CAE technology has become an essential part of mold design and manufacturing. It is used to predict part forming defects, optimize stamping process and mold structure, improve process rationality, and reasonably arrange stamping plans, thereby shortening the mold development cycle, reducing stamping costs, and improving material utilization, so as to transform empirical design into scientific design.

The specific role of CAE/AutoForm analysis software:

➢ a) Conduct process analysis in the early stage of mold design, and use computer CAE software simulation analysis to ensure the rationality of product process,

➢ b) Shorten the cycle of structural design and process design,

➢ c) Use optimized design to find the best molding solution for the product and maximize material utilization,

➢ d) Discover potential problems in advance before product manufacturing (e.g. cracking and wrinkling),

➢ e) Simulate various molding solutions to reduce mold debugging time and cost.

CAE analysis capability example - longitudinal beam series

Part name: left/right front longitudinal beam rear section

Material: B340/590DP

Material thickness: T=2.0

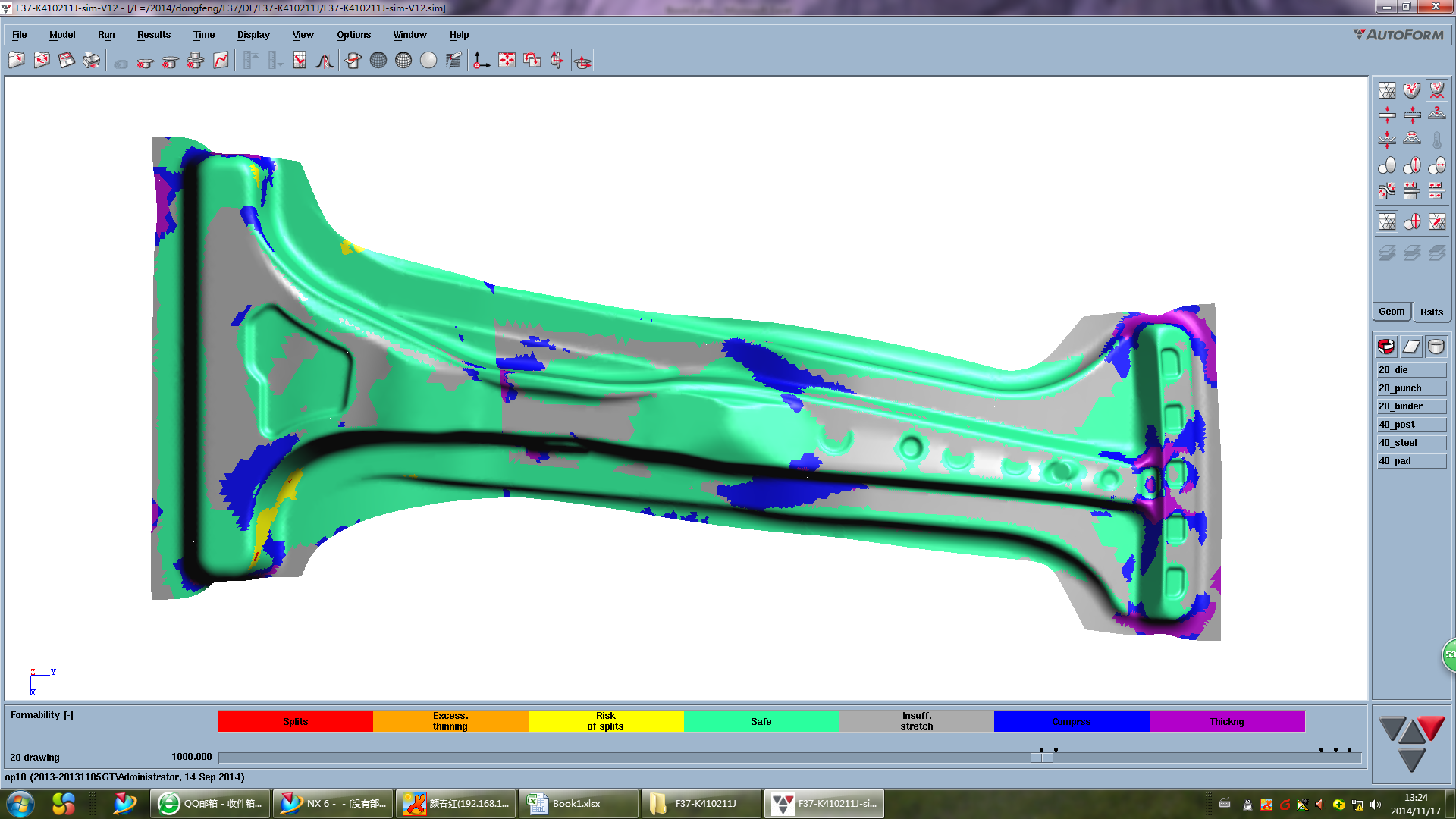

Forming analysis

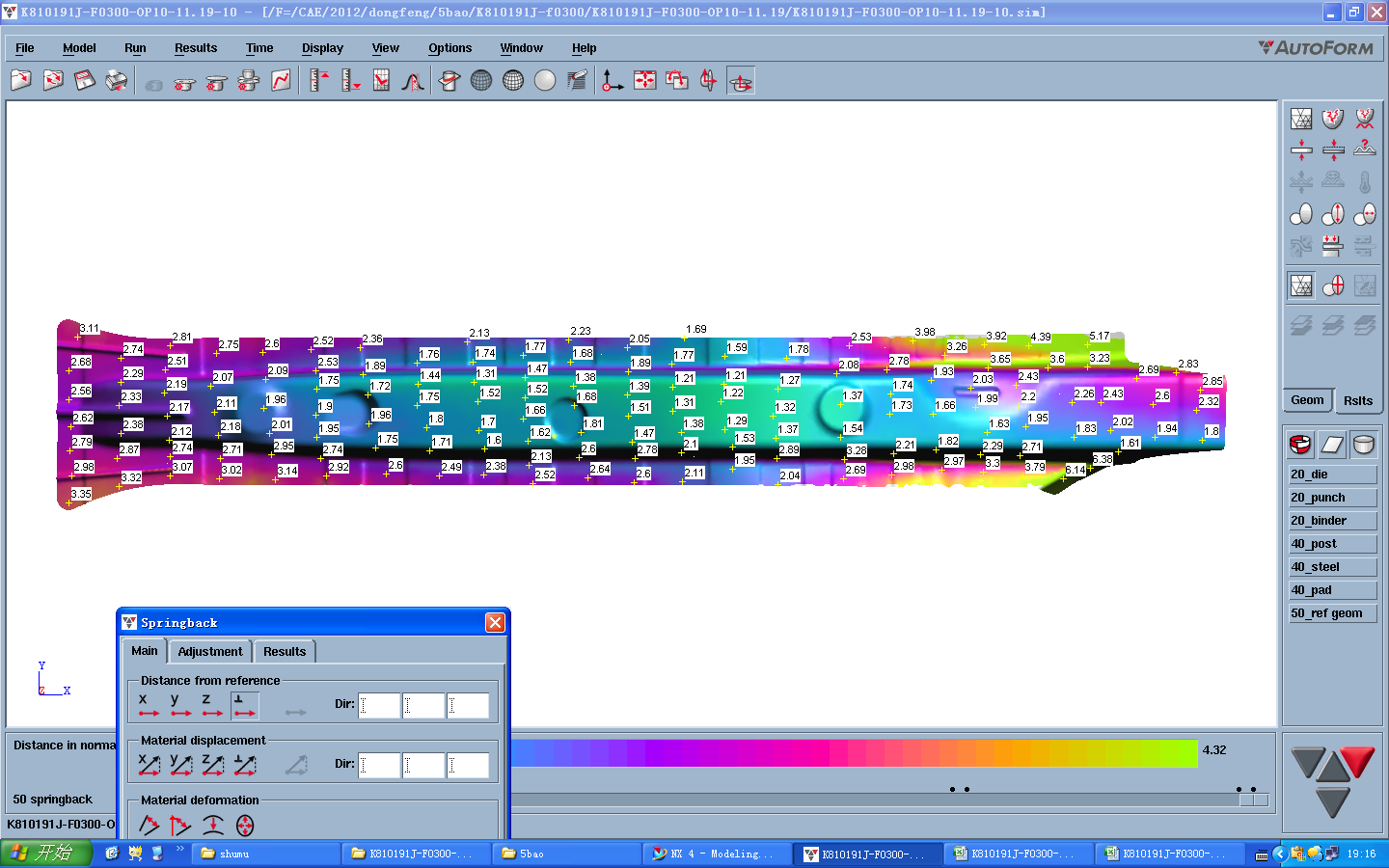

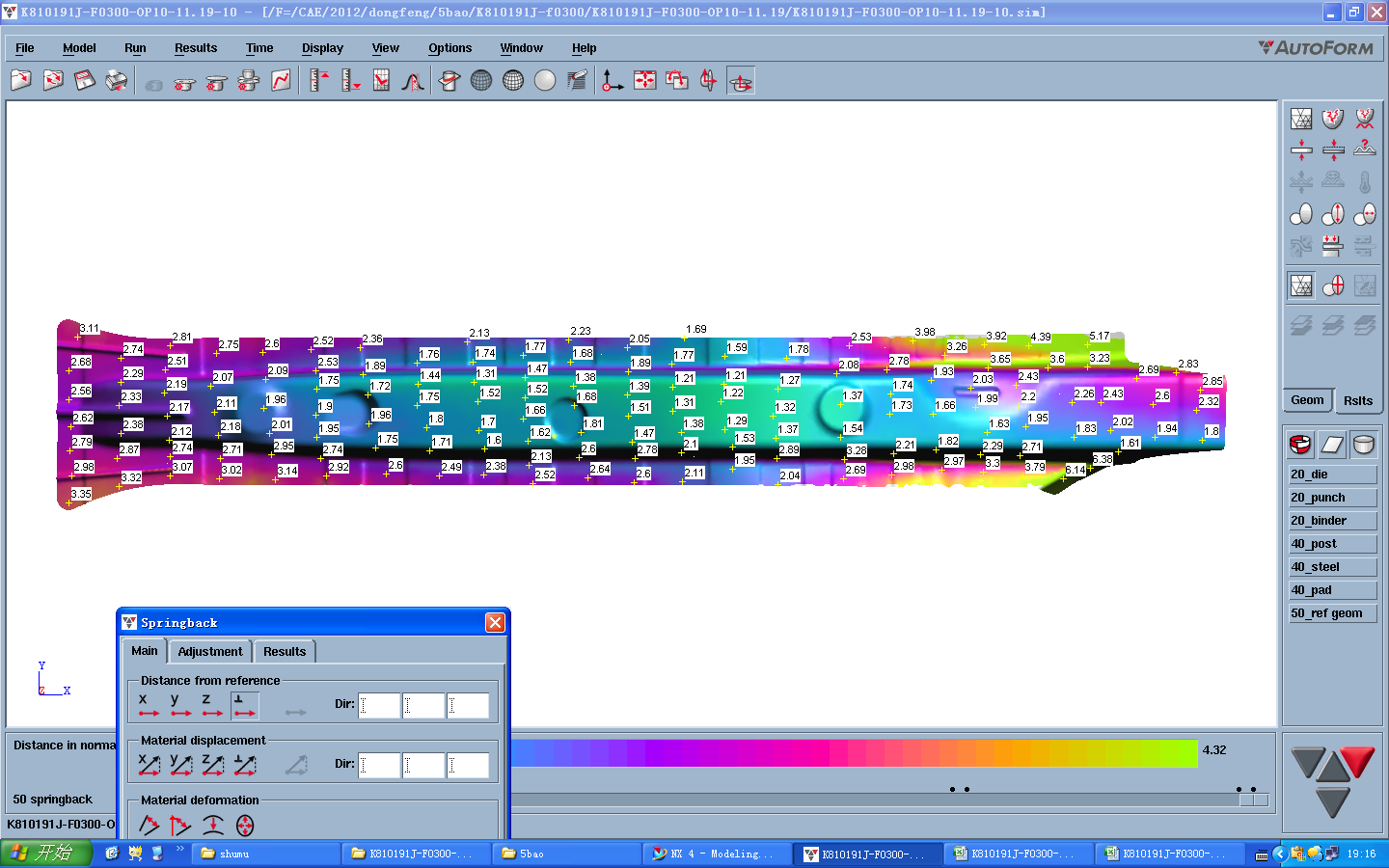

Springback analysis

CAE analysis capability example - longitudinal beam series

Analysis of springback data of each part

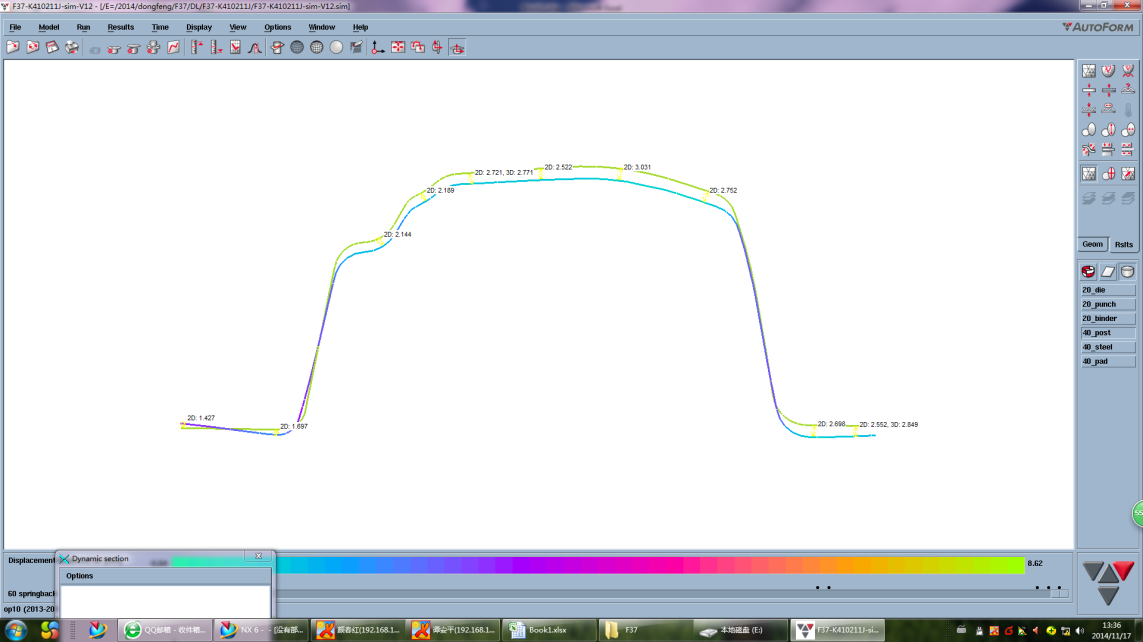

CAE analysis capability example - longitudinal beam series

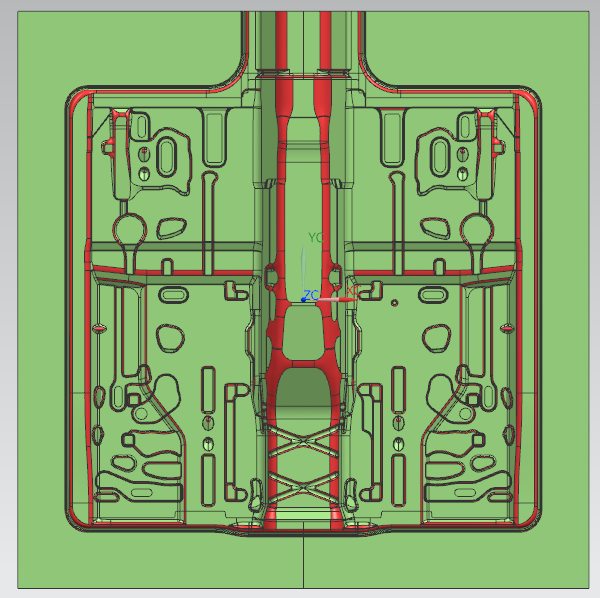

Part analysis and springback compensation processing

CAE analysis capability example - longitudinal beam series

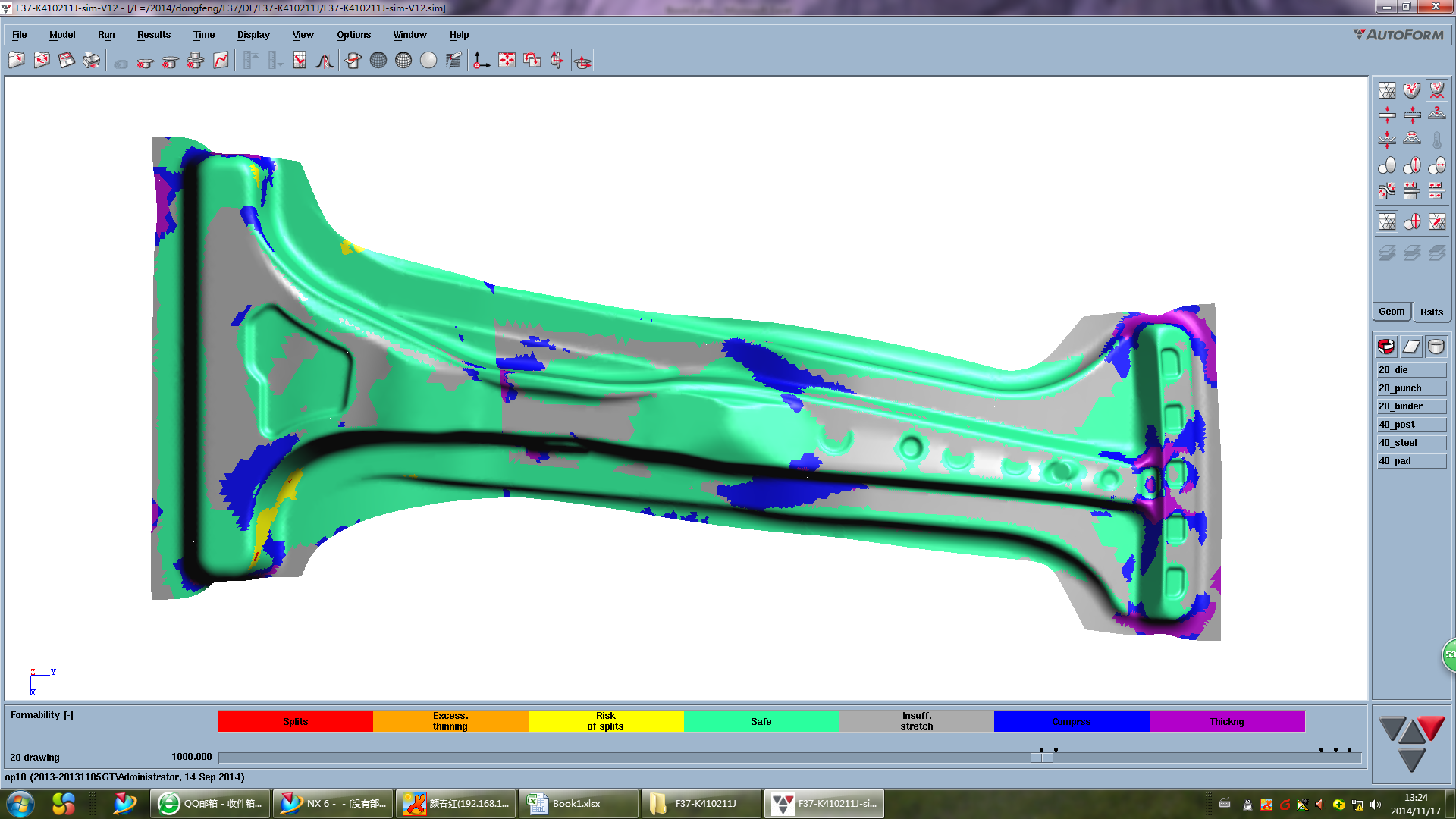

Part name: left/right B-pillar reinforcement plate

Material: QP980 T1.8/D340DP T1.4

Material thickness: T=1.8/T1.4

CAE analysis capability example - longitudinal beam series